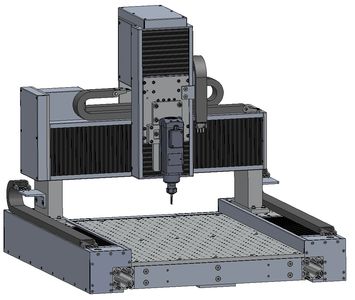

CNC Machine

I've always dreamed of having a custom CNC machine. And over the past five years, I've been working tirelessly to make that happen!

Why make a custom CNC machine?

My requirements are slightly different than a typical machine shop - it needs to be portable, dust proof, and quiet - but also have the power to easily mill non-ferrous metals and hardwoods.

Quite the unique challenge for a small apartment in downtown Boston!

A complete, detailed CAD model was conceptualized and created, including the machine structure, enclosure, frame, and control box.

All custom parts were designed and assembled by me, using only a manual mill, lathe, and other shop tools.

Components like the PC, AC servo controllers, CNC control boards, and others were chosen to optimize the performance, while still unlocking future features with the Linux CNC open source machine controller.

Thorough electrical schematics were created and required a unique set of cables to be made. The standard 4U rack mount control and power shelves easily integrate with the rest of the machine.

FEA simulations were completed on all crucial components like the gantry and spindle to ensure the machine maintained its desired stiffness under stress (10N/um).

Metrology equipment like dial indicators, granite parallels, and gage blocks were necessary to align the machine components to each other. The linear rails had less than 10 microns of parallelism error on each axis!

Copyright © 2025 Conor O'Neil - All Rights Reserved.